Leveraging the power of Artificial Intelligence and Augmented Reality to See and Quantify motion waste

Leveraging the power of Artificial Intelligence and Augmented Reality to See and Quantify motion waste

When you observe the Gemba, a lean thinker will instantly see waste. However, even the finest Lean

Thinkers can be blind (or at least partially sighted) when it comes to waste.

One particular waste that the human eye has difficulty discerning is that of wasted motion. We

regularly convince ourselves that human motion is an acceptable part of work.

However, once you realise how much motion waste is present in an associate’s work cycle, you can

start to design their work area to minimise it, improving productivity.

Lean Lens is a tool that uses AI to objectively ‘SEE’ and ‘QUANTIFY’ the motion waste

for you.

By taking a screen recording you can share this insight with colleagues and communicate the need for

change.

Whether you are new to Lean or a seasoned practitioner, you will appreciate the speed and ease

with which you can identify and quantify motion waste.

Often people think that a process is as good as it can be. Then, when you look at the process

through the ‘Lean Lens’ it becomes clear that there is still so much more to go.

Using your phone or tablet and an internet connection you can instantly make visible

transportationwaste and the often difficult to identify motion waste.

This is made possible by combining our AI algorithm and Augmented Reality to create a digital

eye for improvement.

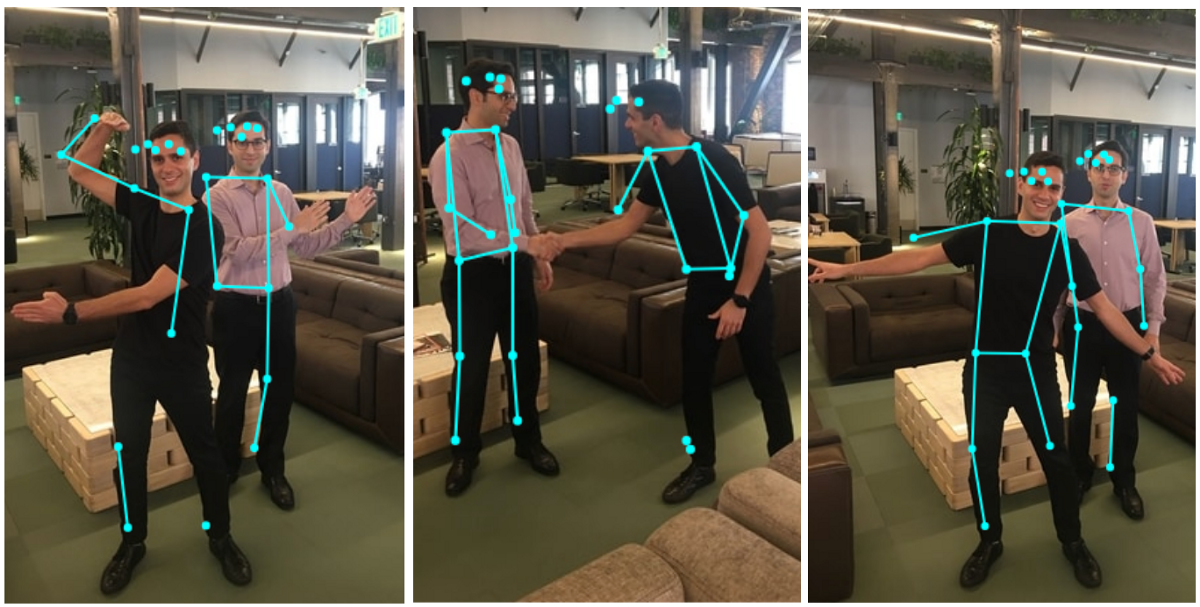

Lean Lens works by first detecting people in the field of view (multiple people can be

detected). Then it measures the location of each person based on several anchor points. The

location of these anchor points is constantly measured every 10ms and the change in distance is

calculated.

If the change in the distance exceeds the set threshold, it is determined to be motion waste.

The threshold or sensitivity can be changed on the app to allow for some movement.

The real-time motion is displayed on the app, along with the number of people detected and the

number of people in motion as per the algorithm.

A rolling average for the % motion is also provided. This can be set anywhere from 10ms to 1

minute. This allows you to see over time how much motion waste is happening in your process over

time.

When looking at a process, there are 7 different kinds of waste (8 if you include ‘underutilised talent).

The 7 lean wastes are:

Lean Lens currently focusses on ‘motion’ waste.

While not all motion in a process is waste. The vast majority is not a value-added activity and is therefore wasteful.

All work can be broken down to value added and non-value-added activity.

Value added is the moment when the raw material or partially finished material is shaped or transformed to bring it closer to the finished product. Non-value-added activity is everything else.

Take a person buttering bread for example. When the butter is being applied to the bread, that’s value added, you are transforming the bread into ‘buttered bread’. So, the associated motion in that moment is not wasteful, however, there is a lot more motion than just applying the butter. Reaching for the butter, moving into position, getting it on to the knife etc.

Lean lens will quantify the total amount of motion in your process, making it more obvious allowing you to reduce the level of motion to match the value-added time as closely as possible.

It won’t tell you which motion is value added or non-value added, you’ll need to use your own knowledge of the process to make that decision.

Are you responsible for a production area that involves people?

Do you want your team to be more aware of waste?

Lean Lens is a great tool that you can use to demonstrate to your team just how much waste

is present in the process.

Once they are aware, you can challenge them to identify ways to make it better. Making their

job easier and your area of responsibility more productive.

You are probably doing regular Gemba Walks. Why not make them more focussed on waste

identification and nurture the improvement mindset.

When you see something, you cannot unsee it, get your team seeing motion waste and

challenging the organisation to do better.

Lean Lens is a great tool to support your Lean training programme. Giving users access to the web app allows them to rapidly understand what motion waste is and just how much of it is present.

While you are most likely great at seeing waste (its everywhere right!). Convincing everyone is

not always so easy. However, even those that are most resistant to making Lean changes cannot

deny the huge opportunity that the ‘Lean Lens’ uncovers.

A great process, one you’ve already improved on lots of times, can still have more than 50%

motion.

Identify this waste, eliminate it and you get greater efficiency, and your associates end the

day with more energy.

1. Open the web app

2. Point the camera at the area of interest

3. Use the rolling average slider to choose between 100ms and 1 minute for a rolling average of

the motion waste visible. Depending on the operation, different rolling averages highlight the

waste better.

4. Use the sensitivity slider to select how much motion triggers the AI to recognise it as

waste. This is useful as sometimes, very small motion maybe acceptable to you. Generally, a

sensitivity level of 300 to 500 is applicable in most cases.

5. Use the insights to take action and reduce waste!

We wanted to keep this technology accessible to as many people as possible, especially within the lean community.

*Free Plan-30 seconds continuous usage

€ 10

Per Month

2 mins continuous usage

Please Signin Before Clicking the pay button

€ 40

Per Month

Unlimited Usage

Please Signin Before Clicking the pay button